Ski Maintenance & Repair: Keep Your Skis in Top Shape

Maintaining your skis is essential for optimal performance, longevity, and safety on the slopes. Regular upkeep ensures a smooth ride, better control, and reduced risk of damage to your gear. Whether you're waxing, tuning, or repairing, here’s everything you need to know about ski maintenance and repair.

Base Repair: Fixing Scratches, Gouges & Core Shots

The ski base is critical for glide and speed. Scratches, gouges, and core shots can slow you down and affect performance.

How to Repair Ski Bases:

Minor Scratches: No need for repair—regular waxing will keep them filled.

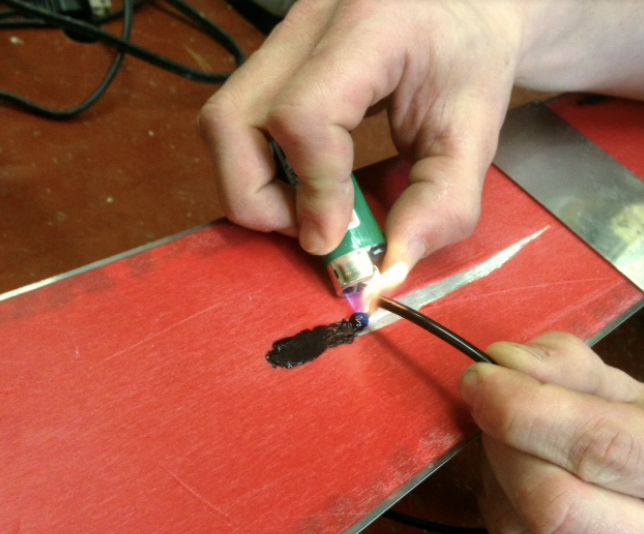

Small Gouges: Use P-Tex (polyethylene repair material) to fill in minor damage.

Core Shots: If the core is exposed, clean the area and fill it with P-Tex or epoxy, then smooth it out with a metal scraper.

Tip: Base damage near the edges requires professional repair to ensure edge integrity.

Edge Tuning: Keeping Your Turns Sharp

Ski edges control grip and turning on snow. Dull edges can make skiing harder, while overly sharp edges can feel too aggressive.

How to Maintain & Tune Ski Edges:

Sharpen with a Diamond Stone or File: Smooth out rough spots and restore sharpness.

Deburr Edges: Use a fine diamond stone to remove nicks or burrs.

Adjust Edge Angles: Most skis have edge angles between 88° and 90°—adjust based on personal preference.

Tip: Edge tuning varies by snow conditions—sharper edges are for hardpack/ice, and duller edges are for powder.

Waxing: Boosting Speed & Glide

A dry ski base slows you down and makes turns less smooth. Regular waxing protects your base and improves glide.

How to Wax Your Skis:

Choose the Right Wax:

Cold weather wax (harder) for icy conditions.

Warm weather wax (softer) for slushier snow.

All-temperature wax for general use.

Hot Waxing: Melt the wax onto the base using an iron. Spread evenly, let it cool, then scrape off excess wax. Buff & Polish: Use a brush or fiber pad to finish the base for a smooth glide.

Tip: Wax every 3-5 days of skiing or whenever your bases look dry.

Binding Adjustment: Ensuring Safe Release

Bindings must release correctly in case of a fall to prevent injury.

How to Maintain Ski Bindings:

Check for Loose Screws & Worn Parts: Tighten anything that’s loose.

Clean & Lubricate Moving Parts: Keeps the release mechanism working smoothly.

Adjust DIN Settings: Based on skier weight, height, ability level, and skiing style. Incorrect settings can lead to injuries.

Tip: Get bindings professionally checked once a season for safety.

Top Sheet Repair: Fixing Cosmetic Damage

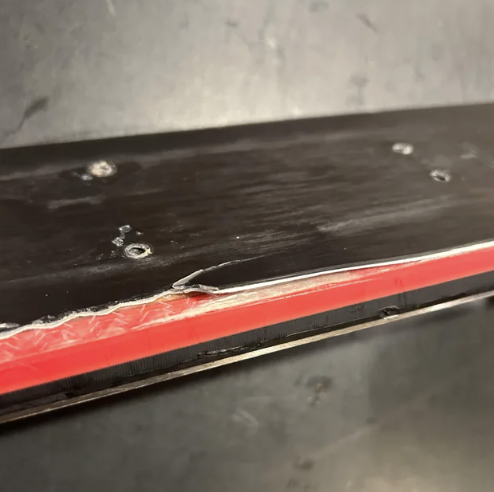

Small chips and cracks in the top sheet are mostly cosmetic, but they can allow moisture into the ski if left untreated.

How to Fix Ski Top Sheets:

For Small Chips: Use epoxy glue to seal the damage and prevent further peeling.

For Larger Cracks: Sand the area, apply epoxy, and clamp it overnight for a strong bond.

Tip: Avoid using super glue, as it can become brittle in cold conditions.

Core Shot Repair: When the Ski’s Core is Exposed

A core shot happens when the ski’s base is damaged so deeply that the core is exposed. If left untreated, water can seep in and weaken the ski.

How to Repair a Core Shot:

Clean the damaged area—remove dirt, wax, or moisture.

Use a base weld or epoxy to fill the hole completely.

Let it cure, then scrape and smooth the surface.

Tip: Deep core shots near the edge should be repaired by a professional ski tech.

Ski Binding Maintenance: Keep Your Bindings Secure

Ski bindings can wear down over time. Regular maintenance ensures they function properly.

How to Maintain Bindings:

Inspect for Wear: Check for cracks, rust, or broken parts.

Test Release Mechanism: Make sure bindings release when needed.

Keep Clean & Dry: Remove snow and ice buildup after skiing.

Tip: If bindings feel loose or inconsistent, take them to a ski shop for a DIN setting check.

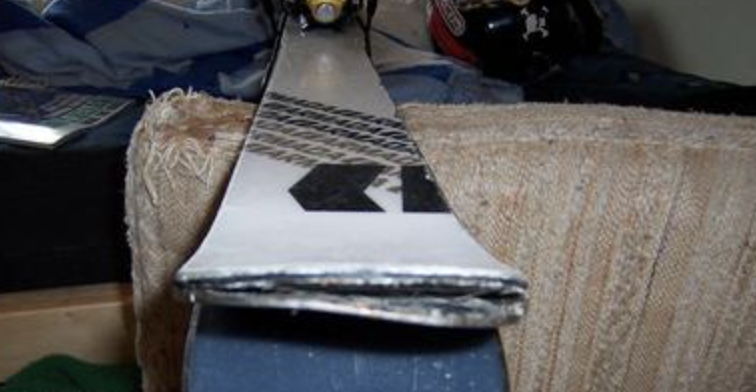

Tip & Tail Repair: Fixing Impact Damage

Ski tips and tails take a beating from collisions, impacts, and rough handling.

How to Fix Tip/Tail Damage:

Minor Cracks/Chips: Use epoxy to seal and prevent further damage.

Delamination: If layers are separating, clamp and glue them back together.

Protective Tape: Cover small dings with strong tape to prevent them from worsening.

Tip: If tips or tails are severely cracked, consider replacing your skis.

Ski Pole Maintenance: Straighten & Repair

Bent poles can affect balance and performance.

How to Maintain Ski Poles:

Fix Bent Poles: Gently bend them back using slow, even pressure.

Check Grips & Straps: Make sure grips are secure and straps aren’t frayed.

Replace Baskets: If baskets crack, swap them out for new ones.

Tip: Carbon poles may snap instead of bending—use caution when trying to fix them.

Ski Inspection: Checking for Delamination & Structural Issues

A ski’s lifespan depends on proper maintenance. Regular inspections can catch problems before they get worse.

What to Look For:

Delamination: If ski layers are separating, glue and clamp them back.

Cracks or Dents: Small cracks can grow, so fix them early.

Edge Damage: If an edge is coming loose, take it to a ski shop for repair.

Tip: Professional ski tuning once a season can extend ski life and enhance performance.

DIY vs. Professional Repairs: When to Go to a Ski Shop

Many ski repairs can be done at home with the right tools, but some require professional expertise.

Do It Yourself:

Waxing & edge tuning

Minor base & top sheet repairs

Adjusting ski poles & bindings

Go to a Pro:

Core shot repairs near edges

Major delamination issues

Binding safety checks

Significant edge damage

Regular ski maintenance and repair ensures better performance, a smoother ride, and longer-lasting gear. Whether you’re fixing minor damage at home or taking your skis to a pro shop, keeping them in top shape is essential for an epic season on the slopes.