The Materials in Ski Construction

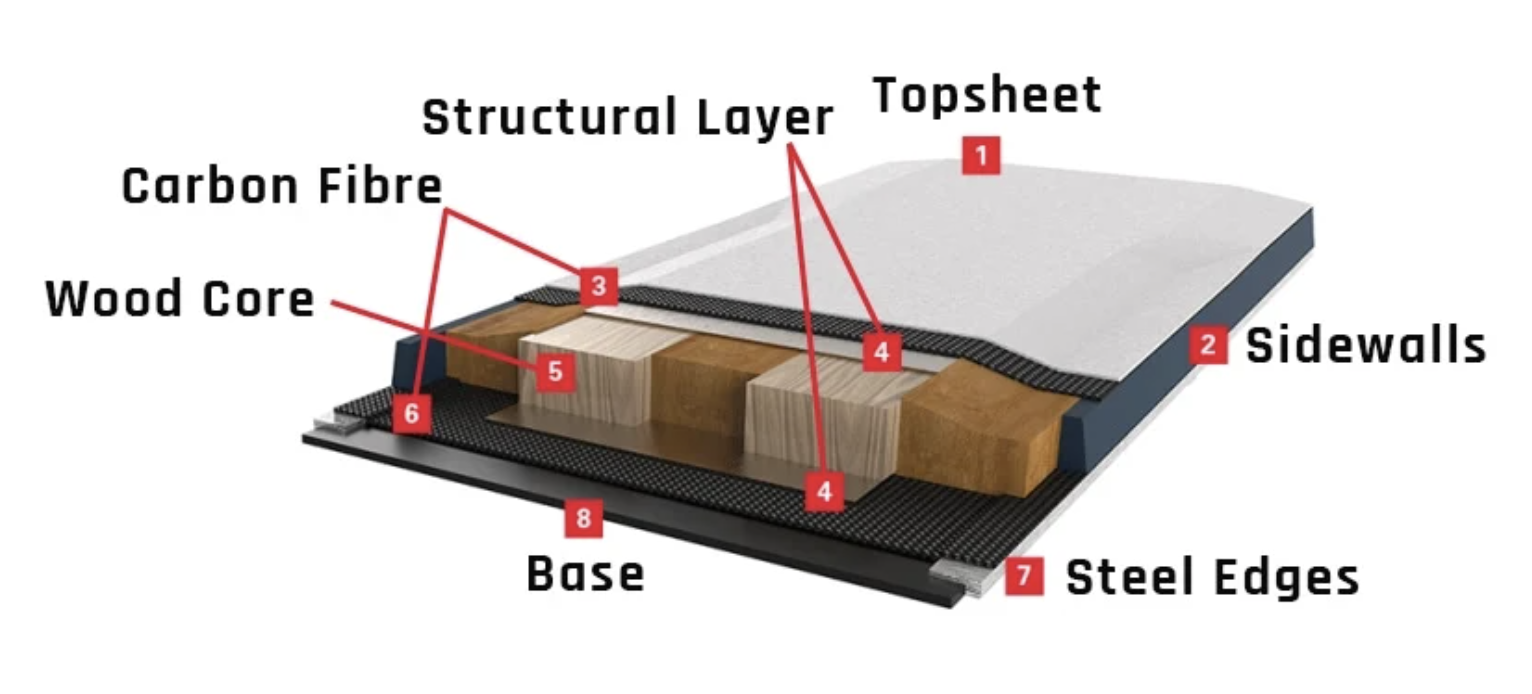

Ski construction has come a long way, with cutting-edge materials and advanced engineering shaping how modern skis perform. The materials used in a ski's construction significantly impact weight, flex, stiffness, durability, dampening, and energy transfer—all of which affect how the ski handles on different terrain and snow conditions.

Manufacturers blend traditional and high-tech materials to fine-tune a ski’s characteristics, balancing responsiveness, stability, and control.

Here’s a detailed look at the key materials found in today’s skis and how they contribute to performance.

Snowlink.com

Core Materials: The Foundation of the Ski

The core is the ski’s backbone, influencing flex, energy return, and durability. Most skis use a wood core, but variations include foam, composite, and hybrid constructions for specific performance goals.

Wood Cores: The Gold Standard

Wood remains the preferred material in high-performance skis due to its resilience, energy return, and natural flex pattern. The type of wood affects the ski’s feel, weight, and responsiveness:

Poplar: a balanced, medium-weight wood offering a lively and responsive ride, common in all-mountain and freeride skis.

Ash & Beech: dense and strong, often used in racing and big-mountain skis for stability at high speeds.

Paulownia & Balsa: extremely lightweight, ideal for touring skis where minimizing uphill weight is crucial.

Maple: durable and energetic, used in freeride and park skis for added pop and impact resistance.

Many manufacturers combine different woods to fine-tune flex and strength, creating multi-wood cores for optimal performance.

Foam Cores: Lightweight, But Less Responsive

Some entry-level (lightweight skis) incorporate foam cores, which reduce weight but lack the energy return and longevity of wood. Found mainly in budget-friendly or rental skis, though some high-end race and touring skis use advanced foam/wood hybrids to balance weight savings and performance.

Kevlar & Composite Reinforcements

Kevlar is a lightweight, high-strength fiber often used to increase durability and impact resistance, reinforcing the ski’s edges and dampening vibrations.

Honeycomb & Synthetic Composites, found in aerospace-inspired designs, reduce weight while maintaining stiffness, commonly seen in high-performance backcountry and touring skis.

Base Materials: Speed, Glide & Durability

The base of the ski is essential for glide, wax retention, and overall durability. Most ski bases use polyethylene (P-Tex), available in two main types:

Some brands infuse graphite or nano-carbon into P-Tex for added speed and durability, especially in race and freeride skis.

Edge Materials: Grip, Precision & Control

Ski edges are crucial for carving and stability, especially on hardpack or icy conditions.

Steel Edges: The Industry Standard

Hardened steel edges ensure durability and sharpness.

Some skis use thicker edges for extra longevity (common in park and freeride skis).

Lightweight aluminum edges appear in some touring skis to reduce weight.

Top Sheet Materials: Protection & Aesthetics

The top sheet is the ski’s outermost layer, designed for durability, scratch resistance, and impact protection.

Common Top Sheet Materials:

Polyurethane or Plastic is lightweight and cost-effective.

Composite Laminates offer improved scratch resistance and structural integrity.

Textured Topsheets provide better grip and durability, especially for touring skis where skins attach.

Laminates & Reinforcement Layers: Strength & Stability

Laminates (or reinforcement layers) determine the ski’s stiffness, torsional rigidity, and energy transfer. These layers are strategically placed above and below the core.

Sidewall Construction: Power Transfer & Durability

Sidewalls impact how energy transfers from the skier to the edge, affecting grip and control.

Some skis use cap construction, where the top sheet wraps over the edges—this reduces weight but sacrifices edge grip. Hybrid designs combine cap and sidewalls for the best of both worlds.

Vibration Dampening: A Smoother Ride

High-speed skiing or variable terrain can cause chatter. Manufacturers use dampening materials to reduce vibration and increase control.

Dampening Materials include:

Rubber/Urethane Layers to absorb shocks for a smoother ride.

Basalt Fiber is a natural alternative to carbon, offering excellent vibration absorption.

Titanal or Metal Layers enhance stability, reducing fatigue on rough snow.

Binding Mounting Plate: Power Transfer & Retention

Metal vs. Composite:

Metal Mounting Plates improve binding retention and energy transmission. Commonly found in race and freeride skis.

Composite Mounting Plates are lighter but less durable. Common in weight-conscious touring skis.

Profile-Specific Materials: Rocker & Camber Adjustments

Manufacturers fine-tune rocker and camber zones by adjusting material thickness and flex:

Thinner Tips & Tails reduce swing weight for better maneuverability.

Thicker Midsections enhance edge hold and stability.

Strategic Reinforcements in Rockered Areas improve powder float and control.

The Future of Ski Materials: What’s Next?

Ski brands are pushing boundaries with sustainable materials, 3D printing, and adaptive flex technology. Future innovations may include:

Self-Healing Bases & Edges for automatic scratch repair.

Nano-Tube & Graphene Reinforcements for ultra-lightweight strength.

Eco-Friendly Bio-Resins & Recycled Materials for sustainable performance.

With continuous advancements, skis are becoming lighter, stronger, and more tailored to different conditions—helping skiers carve harder, float better, and charge faster than ever before.